Neat cutting oils

Showing all 29 results

No sulfur or chlorine. Lubricity and anti-misting properties. Machining non-ferrous metals (brass, copper alloys).

A neat oil aimed at band sawing. Its high fluidity, combined with a specific formulation, make it suitable for use in a ...

A neat oil aimed at band sawing. Its high fluidity, combined with a specific formulation, enables it to be used in a ...

No chlorine or active sulfur. Excellent lubricity. Versatile. Used for working ferrous and non-ferrous metals.

Fluidity, light colour, low odour. Anti-misting properties, low volatility. Compatibility with yellow metals and non-ferrous ...

Light colour, low odour. Lubricity and extreme pressure. Compatibility with non-ferrous metals. Bar turning, threading, ...

Extreme pressure with no chlorine, polarity, lubricity, cooling capacity. Machining on ferrous metals, difficult jobs on ...

Extreme pressure with no chlorine, anti-wear, polarity, enhanced lubricity. Bar turning on stainless steels, hard steels, ...

Lubricity and extreme pressure with no chlorine. Bar turning on stainless steels, high-speed broaching, deep-hole drilling ...

Light colour, low odour. Lubricity and extreme pressure. Compatibility with non-ferrous metals. Bar turning, threading, ...

Light colour, low odour. Lubricity and extreme pressure. Compatibility with non-ferrous metals. Bar turning, threading, ...

Extreme pressure with no chlorine. Compatibility with yellow metals. Cutting and deformation, cold heading, greasing and ...

Sulfo-chlorinated compound oil (EP), reduces friction coefficients. Difficult machining and cold heading on steel, brass, ...

Extra-extreme pressure with no chlorine, synthetic. Low volatility, high flash point (safety). Deep-hole drilling, roller ...

Extreme pressure properties, chlorine-free fluid. Difficult machining on hard steels, including stainless steels. ...

Lubricity, improved surface finishes. Low-volatility, safe (ester-based). Particularly suitable for yellow metals. Milling, ...

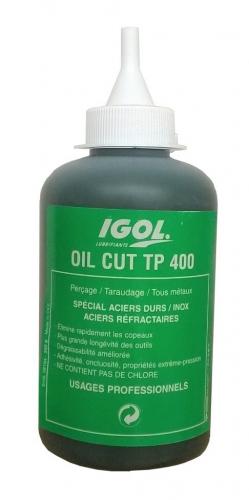

Extreme pressure. Adhesiveness and lubricity. Drilling - tapping. Very difficult jobs on refractory steels.

Extreme pressure with no chlorine. Adhesiveness and lubricity. Drilling - tapping. Very difficult jobs on refractory steels.

Multi-purpose cutting and greasing (hydraulics, slides, reduction gears). Extreme pressure with no chlorine. Anti-wear and ...

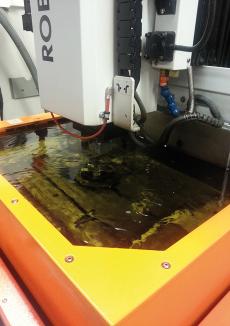

IGOL has developed a very broad range of neat cutting oils for all material removal operations.

Formulated with high-quality mineral or synthetic base oils and rigorously selected additives, our cutting oils create a safe and comfortable working environment.

The advantages offered by our neat cutting oils include:

- The extremely wide choice of viscosities and performance levels

- Their excellent lubricating power and their ability to preserve their properties for long periods (longevity of the oils and of the tools)

- The comfortable working environment (low odour, clear products)

- Their suitability to degreasing